Apron Feeder, YZ Series

Yate YZ series apron feeder, also known as a pan feeder, is a mechanical type of feeder used in material handling operations to transfer (feed) material to other equipment or extract material (ore/rock) from storage stockpiles, bins or hoppers at a controlled rate of speed. The apron feeder is generally applied as a primary or bin feeder application designed for varying applications, from light-duty to severe-duty, from low tonnage to high tonnage of material. Due to its advanced design, excellent configuration and safe operation, this type of apron feeder is widely applicable in mining, cement and metallurgical industries, etc. It also enjoys a good reputation among those fields.

Features

- The apron feeder can convey bigger particle size of conveyed materials, with the diameter of the materials reaching 1.5 meters;

- The bin height of the apron feeder is up to 10 meters, which results in better performance of withstanding greater bin pressure and discharge impact;

- Standard undercarriage components of the apron feeder yields a reliable and long-life feeder;

- Superior flight sealing overlap design of the apron feeder can reduce the leakage of fines;

- The apron feeder provides better feed control to prevent material feeding in downstream equipment from choking;

- This type of apron feeder can reclaim a variety of dry or wet materials of various sizes at a uniform rate;

- This style of apron feeder also creates less noise pollution for quieter operation;

- Less maintenance and better feed control;

- Large anti-friction spherical bearings on the head shaft results in long bearing life;

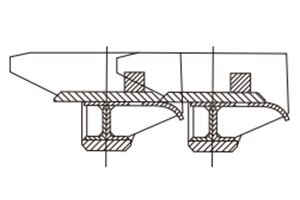

Single circular arc chain plate

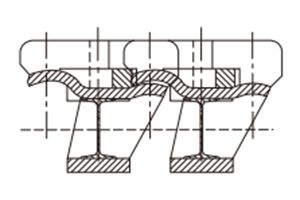

Single circular arc chain plate Double circular arc chain plate

Double circular arc chain plate

Technical data of the apron feeder

| Model | GBZ100-7 | GBZ110-6 | GBZ120-3 | GBZ120-4.5 | GBZ120-10 | GBZ125-4 | GBZ125-6 |

| Dimension (mm) | 1000×7000 | 1100×6000 | 1200×3000 | 1200×4500 | 1200×10000 | 1250×4000 | 1250×6000 |

| Width of the undercarriage chain (mm) | 1000 | 1100 | 1200 | 1200 | 1200 | 1250 | 1250 |

| Shafts distance (mm) | 7000 | 6000 | 3000 | 4500 | 10000 | 4000 | 6000 |

| Maximum feed size (mm) | 600 | 700 | 750 | 750 | 750 | 800 | 800 |

| Feeding speed (m/s) | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 |

| Feeding capacity (t/h) | 100-200 | 100-200 | 100-200 | 100-200 | 100-200 | 150-250 | 150-250 |

| Model of gear box | NGW-S-103 | NGW-S-103 | NGW-S-103 | NGW-S-103 | NGW-S-123 | NGW-S-103 | NGW-S-113 |

| Motor power (kW) | 18.5 | 15 | 11 | 11 | 22 | 11 | 15 |

| Undercarriage chain pitch (mm) | 216 | 216 | 216 | 216 | 216 | 216 | 216 |

| Weight (t) | 27.27 | 24.29 | 21.52 | 24.38 | 36.72 | 23.6 | 26.11 |

| Model | GBZ125-7 | GBZ125-9 | GBZ150-6 | GBZ150-8 | GBZ150-9 | GBZ160-5 | GBZ160-6 |

| Dimension (mm) | 1250×7000 | 1250×9000 | 1500×6000 | 1500×8000 | 1500×9000 | 1600×5000 | 1600×6000 |

| Width of the undercarriage chain (mm) | 1250 | 1250 | 1500 | 1500 | 1500 | 1600 | 1600 |

| Shafts distance (mm) | 7000 | 9000 | 6000 | 8000 | 9000 | 5000 | 6000 |

| Maximum feed size (mm) | 750 | 750 | 900 | 900 | 900 | 1000 | 1000 |

| Feeding speed (m/s) | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 | 0.04-0.1 |

| Feeding capacity (t/h) | 150-250 | 150-250 | 200-300 | 200-300 | 200-300 | 200-350 | 200-350 |

| Model of gear box | NGW-S-113 | NGW-S-113 | NGW-S-123 | ZJX-8 | ZJX-8 | NGW-S-113 | NGW-S-123 |

| Motor power (kW) | 18.5 | 22 | 22 | 22 | 22 | 22 | 22 |

| Undercarriage chain pitch (mm) | 216 | 216 | 216 | 216 | 216 | 216 | 216 |

| Weight (t) | 29.16 | 35.69 | 31.4 | 40.33 | 44.54 | 30.13 | 34.63 |

| Model | GBZ160-8 | GBZ180-8 | GBZ180-10 | GBZ200-12 | GBZ220-10 | GBZ240-5 | GBZ240-10 |

| Dimension (mm) | 1600×8000 | 1800×8000 | 1800×10000 | 2000×12000 | 2200×10000 | 2400×5000 | 2400×10000 |

| Width of the undercarriage chain (mm) | 1600 | 1800 | 1800 | 2000 | 2200 | 2400 | 2400 |

| Shafts distance (mm) | 8000 | 8000 | 10000 | 12000 | 10000 | 5000 | 10000 |

| Maximum feed size (mm) | 1000 | 1100 | 1100 | 1200 | 1350 | 1450 | 1450 |

| Feeding speed (m/s) | 0.04-0.08 | 0.04-0.08 | 0.04-0.08 | 0.04-0.08 | 0.04-0.08 | 0.04-0.08 | 0.04-0.08 |

| Feeding capacity (t/h) | 200-350 | 250-400 | 250-400 | 250-450 | 300-500 | 300-800 | 300-800 |

| Model of gear box | ZJX-8 | ZJX-17 | ZJX-17 | ZJX-17 | ZJX-17 | ZJX-8 | ZJX-28 |

| Motor power (kW) | 22 | 30 | 37 | 55 | 55 | 30 | 55 |

| Undercarriage chain pitch (mm) | 216 | 216 | 216 | 228.6 | 228.6 | 216 | 228.6 |

| Weight (t) | 43.23 | 45.26 | 55.18 | 75.3 | 66.34 | 36.52 | 72.25 |

Shenyang Yate is over 20 years of experience in the rock crushing industry. As an experienced rock crushing equipment manufacturer, we can develop and produce portable and economic coarse crushing systems that meet your various needs for the economic and reliable performance in the economic and mobile crushing industry. We are capable of offering mobile stone rock crushers with a variety of configurations to perfectly match different operational requirements. Our rock crushing machines are cost-effective and we are able to handle the entire size reduction process including crushing, grinding, screening, feeding, .etc. Our movable crushing and grinding equipment are also featured with innovative and dynamic crusher processing technologies that can make your material handling more accessible and reachable. So, if you’d like detailed information about our crushing machines and full-service, just feel free to email us or give us a call.

Get in Touch